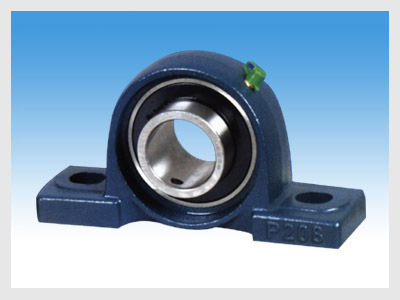

Bearing Housing

Product Details:

- Inside Diameter 32 mm

- Precision Rating ISO Class 6

- Retainer Machined brass cage

- Lubrication Type Oil

- Cage Material Brass

- Thickness 25 mm

- Bearing Type Pillow Back Bearings

100 INR

X

Bearing Housing Price And Quantity

- 100 INR

- 10 Piece

Bearing Housing Product Specifications

- Brass

- 25 mm

- 32 mm

- 90 mm

- Double Lip Seals

- Fixed up to 4.5 kN static, 2.7 kN dynamic

- Machined brass cage

- Stainless Steel

- Oil

- 3600 RPM

- Single Row

- 32 mm

- Split housing with mounting bases, flanges for secure installation

- Pillow Back Bearings

- ISO Class 6

Bearing Housing Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 5000 Piece Per Day

- 1 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

Our impeccably safe and secure delivery of bearings is highly appreciated among our clients. Our highly recognized Bearing Housing is made up of cast iron. These housings can also be made up of spheroidal graphite cast iron or cast steel. These components of our Bearing Housing depend of the applications in which they will be used in. Our housings are durable for a long time period.

Features:

- These housings are developed using latest technology

- These bearings are capable of giving satisfactory performance

- These bearings are available at reasonable rates

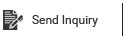

Engineered for Harsh and Hygienic Environments

Crafted from stainless steel with a smooth, anti-rust coating, this bolt-on flange pillow block housing stands out for exceptional corrosion resistance. Suited to both food-grade and high-moisture applications, it maintains integrity in aggressive settings, delivering long-lasting performance and reliability.

Precision and Versatility in Mounting

With a precise ISO Class 6 rating and a split housing structure, this product ensures accurate fit and easy installation using M10 bolts. The rectangular pillow block shape and mounting flanges provide secure attachment for motors, pumps, and conveyors in a variety of industrial settings.

Low Noise and Easy Maintenance

Engineered to operate quietly, the bearing housing optimizes machine efficiency. Maintenance is straightforward thanks to simple grease or oil lubrication and easy access to the housing, reducing downtime for cleaning or routine care. Double lip seals also help keep contaminants out, extending operational life.

FAQs of Bearing Housing:

Q: How is this bearing housing installed on my conveyor or pump system?

A: The bearing housing is designed for straightforward installation using M10 bolts through its bolt-on flange and split housing structure. Simply align it to your machinerys mounting base, secure it with the specified fasteners, and ensure the 32 mm shaft fits snugly within the housing.Q: What benefits does the high corrosion resistance provide in wet or food-grade environments?

A: With its stainless steel construction and smooth anti-rust coating, this housing resists corrosion even in wet, humid, or chemically aggressive settings, making it ideal for food processing, beverage, or cleaning-intensive industries that demand hygiene and durability.Q: When should I lubricate or maintain this bearing housing?

A: Routine maintenance involves periodic lubrication with either oil or grease, depending on your operational demands. Easy-access points in the housing simplify re-lubrication; follow your machinerys recommended schedules or inspect at set intervals for optimal longevity.Q: Where can this bolt-on pillow block bearing housing be used?

A: This housing is suitable for a variety of industrial and agricultural applications, such as conveyors, fans, pumps, and machinery exposed to moisture or needing hygienic standards. Its robust design and sealing make it adaptable to food processing and wet industrial areas.Q: What is the process for replacing the bearing or seals in this housing?

A: To replace the bearing or seals, detach the housing using the mounting bolts, carefully split the housing, and remove the worn parts. Install new components, reassemble the split structure, and secure the housing back into position. Lubricate accordingly before resuming operation.Q: What makes this bearing housing advantageous compared to standard models?

A: Beyond high corrosion protection, it offers a noise-reduced design, split housing for maintenance ease, ISO Class 6 precision, double lip seals to block contaminants, and a robust load rating. These features enhance equipment performance, reliability, and hygiene in demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pillow Block Bearings' category

|

TECHNO OVERSEAS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free