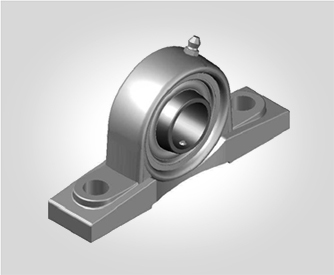

High Temperature Bearings

Product Details:

- Lubrication Type Grease

- Bearing Type Roller Bearing

- Material Carbon Steel

- Seals Type ZZ

- Number Of Rows Single Row

High Temperature Bearings Price And Quantity

- 10 Piece

- 1100 INR

High Temperature Bearings Product Specifications

- Grease

- Carbon Steel

- Roller Bearing

- Single Row

- ZZ

High Temperature Bearings Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 5000 Piece Per Day

- 14 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

High Temperature Bearings

Keeping in track with huge demands of our clients, we provide supreme quality High Temperature Bearings. These bearings are manufactured under stern supervision of adroit professionals at our vendors' end using top grade metal alloy. The offered bearings are widely used for the purpose of load accommodation in mechanical parts which are exposed to high temperatures. Moreover, these High Temperature Bearings are available with us at very reasonable rates. ENC High Temperature Bearings suitable for applications characterised by high temperatures. These types of bearings can be used in 150 degree C and 320 degree C temperature working environments.

Features:

- High temperature resistance

- Rigid structure

- Optimum strength

- High finish

TECHNICAL CHARACTERISTICS

- AISI 52100 Steel (High carbon quality steel )

- Manganese Phosphate surface treatment

- Increased radial clearance to compensate expansions

- ZZ and OPEN available

FIELDS OF USE

- Brick manufacturing Units

- High temperature rollers

- Iron and steel industry

- Glass manufacturing

Superior Performance in Extreme Conditions

These carbon steel roller bearings, fitted with grease lubrication, excel in high temperature environments. The ZZ seals provide dual shield protection against contaminants, prolonging bearing life and reducing maintenance frequency. Ideal for continuous operation in factories, they maintain stability and reliability even under elevated thermal loads.

Trusted Supply and Quick Availability Across India

As a leading importer, supplier, and trader of high temperature roller bearings, we ensure swift delivery and consistent stock availability throughout India. Our network caters to industries that require durable bearings for uninterrupted production, offering competitive pricing and dependable after-sales support.

FAQs of High Temperature Bearings:

Q: How do high temperature roller bearings with grease lubrication function under intense heat?

A: These bearings use specialized grease with a high thermal tolerance, ensuring the rolling elements and raceways are properly lubricated even at elevated temperatures. The carbon steel structure and ZZ seals together help the bearings resist heat and retain lubricants, which prevents premature wear and maintains operational efficiency.Q: What are the benefits of choosing carbon steel roller bearings with ZZ seals for industrial applications?

A: Carbon steel offers exceptional strength, durability, and resistance to deformation under stress. ZZ seals provide double-sided shielding, keeping out dirt, dust, and moisture. This combination increases bearing lifespan, lowers maintenance requirements, and enhances overall reliability in demanding environments.Q: When is it recommended to use single row roller bearings in high temperature applications?

A: Single row roller bearings are ideal for scenarios requiring moderate load capacity and space savings. They are recommended when reliable performance and heat resilience are needed, such as in manufacturing, metallurgy, and processing plants where temperatures regularly exceed standard limits.Q: Where are these high temperature grease-lubricated roller bearings commonly used in India?

A: Industries such as steel production, cement plants, textile mills, and heavy machinery manufacturing in India frequently utilize these bearings. Their robust material and efficient sealing make them suitable for environments exposed to high heat, dust, and vibration.Q: What is the process for importing and supplying these high temperature roller bearings in India?

A: As an importer, supplier, and trader, the process involves sourcing bearings from reputable manufacturers, ensuring compliance with international standards, and maintaining adequate inventory. Distribution across India is managed through streamlined logistics to meet the timely needs of clients.Q: How does using grease as a lubrication type improve the longevity and performance of these roller bearings?

A: Grease provides continuous lubrication and acts as a barrier against contaminants. In high temperature scenarios, specially formulated greases prevent metal-to-metal contact and reduce friction, extending bearing service life and ensuring smooth operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'High Temperature Bearing' category

|

TECHNO OVERSEAS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS